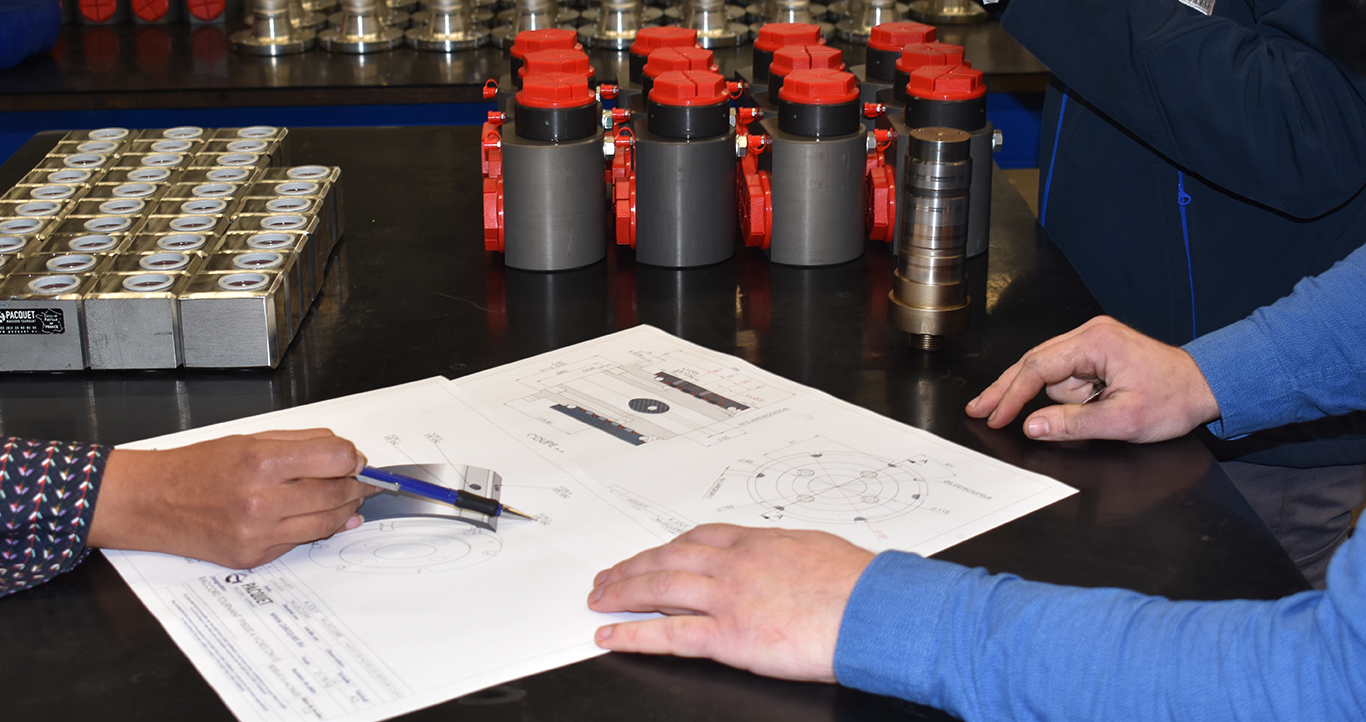

CO-DEVELOPMENT OF ROTARY UNIONS

ENTRUST US WITH YOUR SPECIFICATIONS

Our technicians/engineers will ask you questions about your process, the operating conditions of the rotating union as well as the requirements and constraints associated with your installation. They will work with you to ensure that none of the standard rotating joints or adapted standard rotating joints are suited to your application. Once your need for a custom swivel fitting has been ascertained, the Design Office begins the customised study phase with you and fine-tunes your needs with you.

Whether the specifications cover every aspect or just a few elements, don't hesitate to send us any information that could facilitate the study of your swivel fitting:

- Operating conditions

- Photos

- Plan of an existing fitting to be modified

- Drawing of the joint's installation within the process

- Item reference of the equivalent required fitting

- Dimensions

- All the information about the operating environment of the rotating joint

DEVELOPMENT OF NEW FULLY CUSTOMISED ROTARY UNIONS

As part of a new installation, you have to install one or more custom rotating joints. Following the failure of a rotating union that is currently operating on a machine, you have to refit a new swivel fitting that is not included in our standard range. There are many factors that need to be taken into consideration. Working in our offices or directly on your premises, our teams provide the support you need. If there is real added value, don't hesitate to ask our team to come to your site to take measurements and photos in the actual operational surroundings, and conduct a detailed analysis of the environment in which the fitting will be used.

Our objective:

- To develop a rotating joint that meets your installation requirements

- To meet all the operating conditions of the rotating union

- To offer you a high-tech swivel fitting that is tailored to its use, at a cost that is properly understood

IMPROVING THE PERFORMANCE OF EXISTING ROTARY UNIONS

Our Design Office can also assist you, on request, in improving existing products that are still in use, but could be made more productive. Changes in dimensions following a modification of the process or a revision of the operating conditions: our technicians/engineers are at your disposal to find the solution for making your installations more efficient. During the study, if it is necessary, we will give you an outline drawing for validation before costing. At the end of the study, you will receive a detailed cost estimate, a series of finalised outline drawings as well as a deadline for supplying the rotating union.